How to Avoid an Obsolescence Crisis

Obsolescence management is still a relatively nascent topic for many organizations. However, PatSnap has just recently returned from an event in Germany known as COG-D, or rather ‘Component Obsolescence Group Deutschland,’ to give it its full title. During the event we found that obsolescence management is still in the earlier stages for those who are not in the know but is becoming more prevalent and is something that we’ll be hearing more and more about. Meanwhile, patent data and IP analytics is an important aspect in this arena and it was on this topic that PatSnap had its role to play.

What is obsolescence management?

Put simply, obsolescence management describes a formalised methodology for dealing with the transition of a component or part from one of availability to one of non-availability. During the event, the Association of German Engineers (VDI) addressed the main reasons why obsolescence management plays such an important role for organizations. This can include:

- End of Life (EOL), End of Support (EOS), or a Product Change Notification (PCN) from the manufacturer

- The component can no longer be delivered

- The Original Equipment Manufacturer (OEM) or the Original Component Manufacturer (OCM) is no longer active in the marketplace

- The necessary know-how for the production of the part is lost

- New technologies have replaced the former technology

- Changes in national law or legislation that prevent delivery or production

What has this got to do with patents?

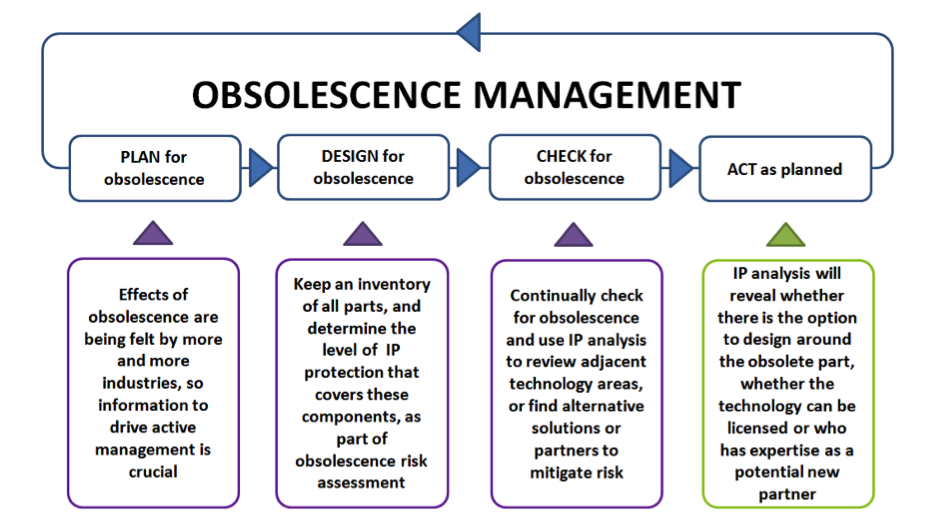

At first glance, it would seem that patents wouldn’t be relevant to product parts or components that are coming to the end of their lives. However, the reality is that patents play a role within every stage of the obsolescence process. Many of the speakers at this quarter’s COG-D event promoted the transition of obsolescence management from a reactive approach to a proactive or even strategic approach. It is within these latter approaches that patents become important.

As part of the pro-active approach, manufacturers are encouraged to think about the risk of obsolescence right at the beginning of the product development phase. Scenarios are planned where the purpose is to consider what action should be taken, in the event that a component becomes obsolete. As the speed of invention increases, more and more components will become obsolete within a shorter time frame. If a manufacturer relies on a specific technology that becomes obsolete, they may consider redesigning the obsolete part, or reverse engineering. However, it must be remembered that patents cover a technology for a period of twenty years, so there is a high chance that the technology will still be protected, leading to potential conflict.

What’s the solution?

As part of the obsolescence management process, companies are increasingly creating databases that provide an inventory of the components and how they should be managed throughout their life cycle. We would recommend that patent information becomes an integral part of this record of information. In this way, patent information feeds into the recommended steps for proactive obsolescence management at every stage:

Wider benefits of IP Analysis in obsolescence management

By using IP analysis to plan for risk and seek out new alternatives, companies will also find that they have much more information and data to hand that will inform wider business decisions or provide greater competitive intelligence. As a European Commission Report has stated, patents contain detailed technical information which often cannot be found anywhere else: indeed, up to 80% of current technical knowledge can only be found in patent documents.

Your recommended content

-

Patsnap Releases 2023 Global Innovation Report: The Brilliant Names to the Dynamic Landscape of Innovation

Category: Article | Category: eBook | Category: Research Tag | Category: Whitepaper

Wednesday, November 15, 2023

The Global Innovation 100 and Global Disruption 50 transcend individual entities, each representing a small innovation ecosystem with numerous subsidiaries. Through the innovation data of these companies, we gain insights into the characteristics, structures, and trends of global innovation.

-

Patsnap’s 2023 Disruption 50: A Closer Look at Tomorrow’s Innovators

Category: Article | Category: eBook | Category: Research Tag | Category: Whitepaper

Wednesday, November 15, 2023

Through active growth, the Global Disruption 50 have quickly established solid technology quality and profound technology influence that are comparable to that of the Global Innovation 100.

-

Impact of Patsnap’s 2023 Global Disruption 50

Category: Article | Category: eBook | Category: Whitepaper

Wednesday, November 15, 2023

The 2023 Global Disruption 50, 30% of which come from the Information Technology sector, are shifting the world’s innovation focus from a physical world of Atoms, to a digital world of Bits, and then a “world of Atoms empowered by Bits”.