The tin can is dead – long live recyclable food pouches

Tin cans were invented over 200 years ago. After the introduction of the cannery—an efficient production line that these days can fill around 300 cans per minute—tin cans quickly became the food preservation method of choice.

There were a few teething problems to get past though. It took 40 years for someone to invent the tin opener and after a bit of reputational damage, it was eventually decided to stop using lead-based solder to seal them.

Cans provide years of ambient storage protection which—when there’s limited access to refrigeration—makes them perfect for leaving inside a bunker at wartime or the back of a cupboard for a rainy day.

However, the tin can was predicted to be inducted into the annuls of history with the development of food pouches in 1978.

Food pouches promised the consumer:

- extended shelf life

- handy, space-saving portable food

- a better taste to canned food

- resealable potential for product conservation

- reduced product wastage

- easy open packaging

and for manufacturer/suppliers:

- improved vertically displayed graphic presentation for increased eye-appeal

- lightweight and space-saving for delivery, storage and display

- multiportion packs for single use sauces in food service and restaurants

- cheaper than rigid plastics

- less energy required to produce than tin cans

But it wasn’t until 1999 that these revolutionary packaging products really made it onto the supermarket shelves—and that was for pet food.

19 more years has gone by and things still haven’t moved much further. After a bit of market research (a hunt around my local supermarket) I spotted baby foods, microwave rice, pet food and confectionery in pouches—which isn’t exactly domination from the heir apparent. Yet food pouches are predicted to have an explosion in adoption. Some might call it a future mega-trend.

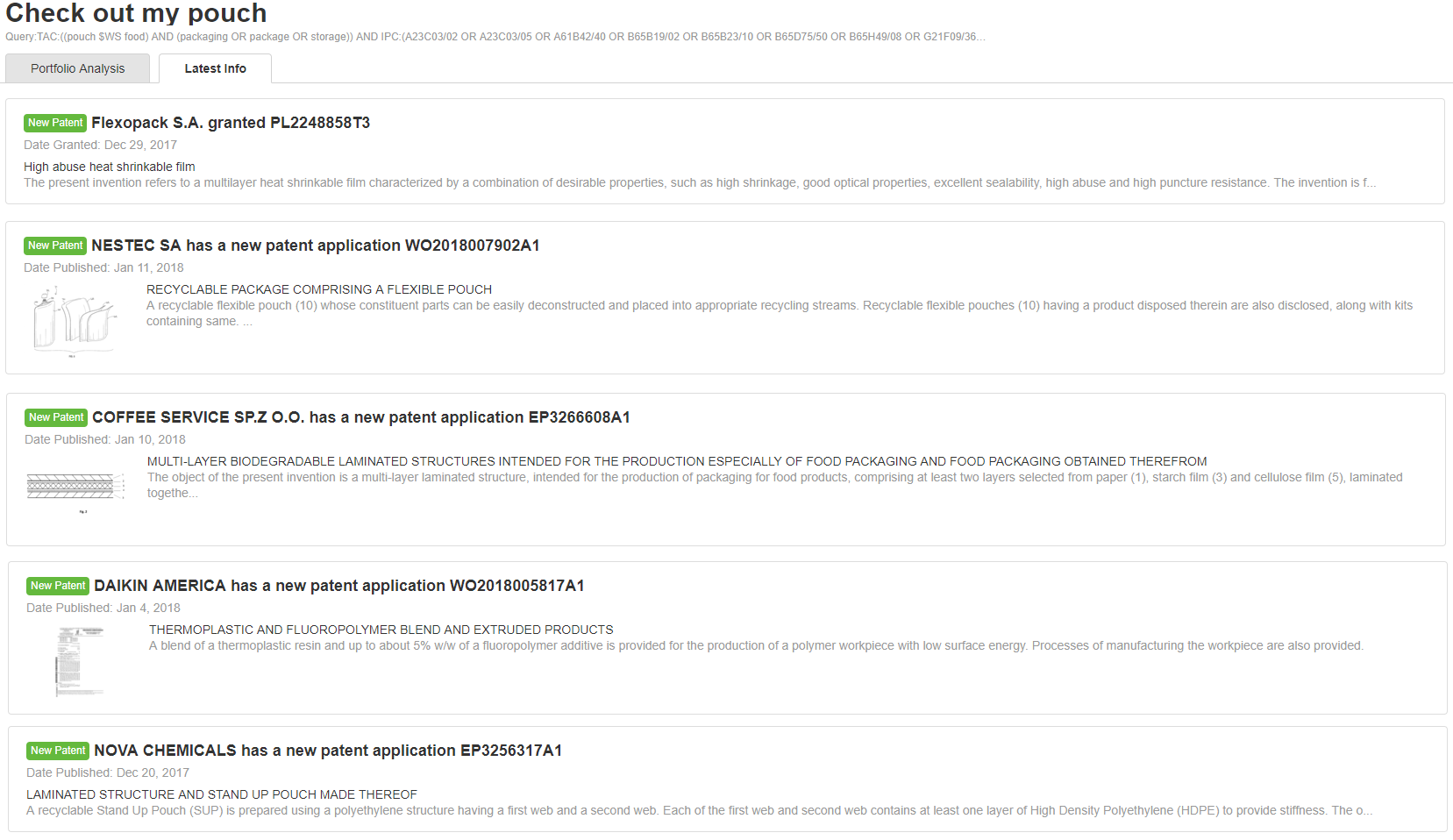

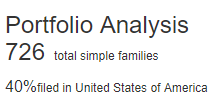

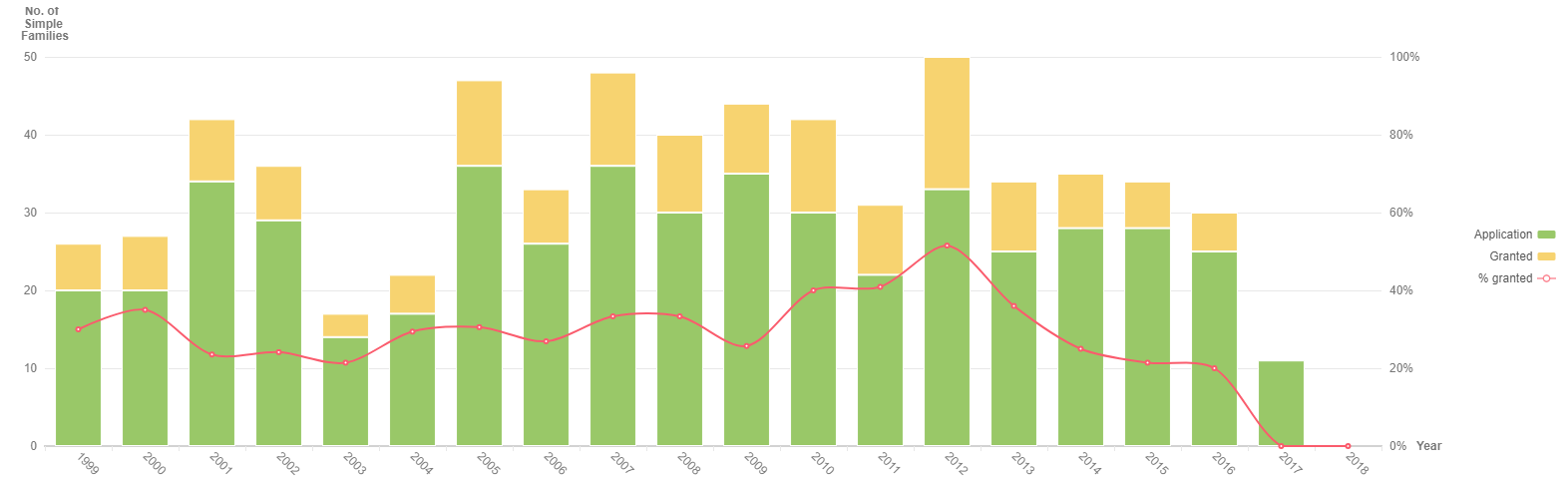

Global intellectual property data, sourced from the PatSnap platform, shows 726 simple patent families linked to food pouch research and development. We can see the general trend has seen around 25-35 patents filed each year over the past 20 years. Hardly the typical J-curve of the next big thing.

Grant rates peaked in 2012 at 51%—although they are currently on the decline with only 1 in 4 patent applications being granted. And the USA is leading the charge for patent filings.

The international patent classification trends for patents filed in the past five years are predominantly:

- B32B27 – Layered products comprising synthetic resin

- B65D81 – Containers for contents with transport/storage problems

- B65D75 – Packages with articles enclosed in material

It seems that in principle, many of the foundations are in place for the coronation. Yet the tin can isn’t ready to renounce its position—not until the pouch can answer a few major concerns. Fortunately, intellectual property data shows why the packaging and plastics giants are buffing up the crown jewels—and it might just happen for real this time.

Plastics aren’t bad

Plastic has had a tough time in terms of reputation. According to the Ellen Macarthur Foundation 40% of plastic waste goes straight to landfill and a shocking 32% is leaking into the environment. It’s predicted that by 2050 there will be more plastic in the sea than fish.

Early adopters of the food pouch included baby foods and soft drinks. They generally used mixed material pouches. Mixed material pouches offered extended shelf-life products—but these pouches are notoriously challenging to recycle.

Some packaging manufacturers appear to be accepting the cost factor of sustainable modern packaging. Many have commenced the move away from metal film layers—replacing them with all-plastic pouches that consumers can recycle on the doorstep.

Recyclable polyethylene terephthalate (PET) is fast becoming the packaging material of choice for many food and report by Smithers Pira, PET packaging is forecast to reach 21.2 million tons by 2021. Sustainability and weight are expected to be their major development considerations.

Aware we only have this one planet, conscientious shoppers are looking for sustainable packaging—biodegradables, recyclables and compostables—with a minimal carbon footprint. So, manufacturers need to be on top of this market-demand change and ensure the infrastructure to switch from mixed materials to all plastic pouches is in place.

Cost and speed

Manufacturers stand to benefit from this shift away from cans and other rigid packaging. Adopting flexible, lightweight containers for products can reduce distribution and storage costs considerably—saving, potentially, up to 90% on pallet and warehouse space. But that’s not saying there aren’t some alternative financial challenges.

Aside from the costs for food packaging manufacturers to replace their machinery, the raw materials for tin cans are cheaper—around $0.01 cent versus pouches which currently start around $0.08 cents.

As previously mentioned, a good cannery can fill 300 cans per minute. A pouch filling machine maxes out at around 200 per minute. That’s a productivity loss of potentially 50 million units per year. And this could effectively cause a financial loss of over $6.8 million each year.

For any budding inventor who really wants to find value in food pouches, this is a potentially huge incentive.

Real food

The Instagram generation is stepping away from preservatives and artificial ingredients and toward deli counters and vegetable aisles. Although the nature of millennial shopping and eating habits, suggests they’re heavily contributing to the 7 million tonnes of food wastage produced in the UK each year.

Cryovac has an answer for the millennials. It is the food packaging division of Sealed Air Corp (inventors of Bubble Wrap), and the most prolific patenting company attempting to perfect food pouches. Cryovac currently owns 46 patents relating to this specific area.

“US20140314920A1—Multilayer film having passive and active oxygen barrier layers”, worth an estimated $4.3 million. It has 24 individual patent documents globally protecting the contents of this patent—and this patent could potentially remain valid for another 15 years.

It details a multilayer film with an active oxygen barrier core sandwiched between two passive or active barrier layers. One variation of its composition contains thermoplastic resin with carbon-carbon double bonds, a transition metal salt, and an oxygen barrier polymer. The multiple layers’ oxygen absorption capacity results in an extension of the useful shelf life for foodstuffs.

While Cryovac might have the largest volume of patents, there’s other patenters solving these sorts of problems too.

Curwood, now owned by Bemis, invented “US8530012—Packaging articles, films and methods that promote or preserve the desirable color of meat” worth an estimated $8.1 million—the most valuable patent for food pouches. The patent describes food packaging that contains a myoglobin blooming agent and an oxygen barrier layer to ensure fresh meat retains an attractive surface colour while extending shelf life.

Contamination risks

Tin cans are impermeable. ‘Blown’ cans are easy to spot due to the swelling/explosions that occur with bacterial spoilage. Pouches on the other hand have potential spoil and contamination risks from pinholes, flex cracks or poor sealings.

Greek packaging gods, Flexopack had patent “PL2010159847T— High abuse heat shrinkable film” granted in December. This invention details a film that has high shrinkage, good optical properties and excellent sealability. More importantly it also features high abuse and high puncture resistance.

The future of the pouch

Innovations should (even if they don’t always) be looking to make improvements on what has gone before. Judging by the latest patent applications, the race is on for food pouches that are cheaper to produce, faster to make, easier to use and greener.